Property energy efficiency impacts your bottom line. Higher energy costs reduce profitability while inefficient systems require frequent repairs and early replacement. Simple maintenance tasks can deliver immediate energy savings without major capital expenditure.

These five maintenance strategies provide instant results. Implementation requires minimal investment but generates measurable returns through reduced utility costs and extended equipment lifespan.

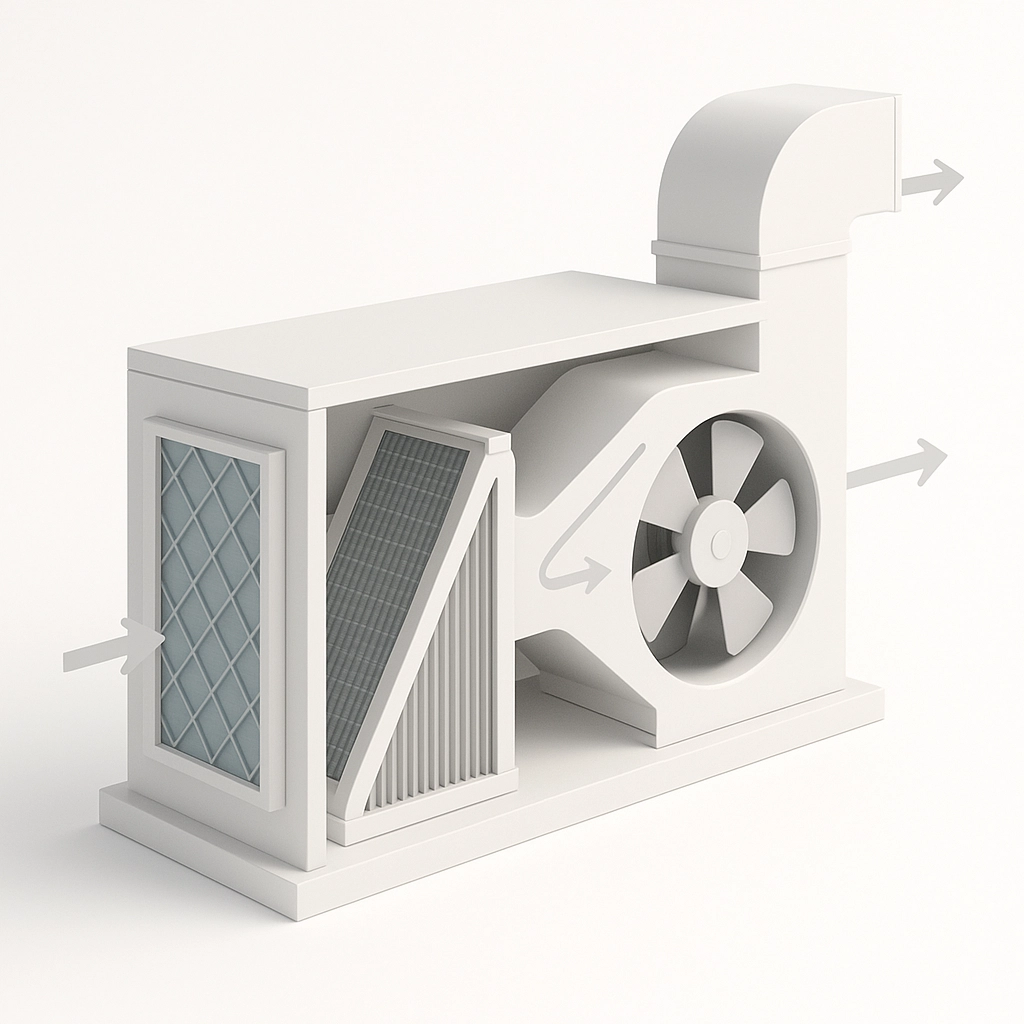

1. Maintain HVAC Systems and Replace Filters Regularly

HVAC systems consume 40-50% of a building's total energy. Regular maintenance ensures optimal performance and prevents energy waste.

Replace air filters every three months. Dirty filters force systems to work harder, increasing energy consumption by up to 15%. Clean filters improve airflow and maintain proper system pressure.

Schedule annual professional HVAC servicing. Technicians clean internal components, check refrigerant levels, and calibrate controls. This prevents minor issues from becoming major energy drains.

Clean evaporator and condenser coils quarterly. Dirty coils reduce heat transfer efficiency, causing systems to run longer to achieve desired temperatures. Use appropriate cleaning solutions and allow coils to dry completely before restarting equipment.

Check and clean ductwork connections. Loose joints allow conditioned air to escape into unconditioned spaces. Apply duct sealant or metallic tape to secure connections. Inspect accessible ductwork for damage or disconnected sections.

Clear debris from outdoor condenser units. Remove leaves, grass, and other obstructions within two feet of the unit. Trim vegetation to maintain adequate airflow. Clean the unit's exterior fins with water and mild detergent.

Verify thermostat accuracy using a separate thermometer. Inaccurate thermostats cause systems to overcool or overheat spaces, wasting energy. Replace batteries in wireless thermostats annually.

2. Seal Air Leaks and Replace Weatherstripping

Air infiltration accounts for 25-30% of heating and cooling energy loss. Identifying and sealing leaks provides immediate energy savings.

Inspect weatherstripping around doors and windows. Replace cracked, compressed, or missing weatherstripping every two years. Use appropriate materials for each application: adhesive-backed foam for irregular gaps, V-strip for sliding windows, and door sweeps for bottom door gaps.

Apply caulk to stationary joints. Seal gaps around window frames, door frames, electrical outlets, and plumbing penetrations. Remove old, cracked caulk before applying new sealant. Choose appropriate caulk types: silicone for exterior applications, latex for interior use.

Test for air leaks using simple methods. Hold a lit candle or incense stick near potential leak points on windy days. Flame movement indicates air infiltration. Alternatively, use a handheld smoke pen for more precise detection.

Install door sweeps and thresholds. Gaps under doors allow significant air exchange. Adjustable door sweeps accommodate uneven floors while maintaining proper sealing.

Seal electrical outlets and switch plates on exterior walls. Remove cover plates and apply foam gaskets behind them. Use outlet sealers for unused outlets in unfinished areas.

Check basement and attic penetrations. Seal gaps around pipes, wires, and ducts passing through floors and ceilings. Use expanding foam for larger gaps and caulk for smaller openings.

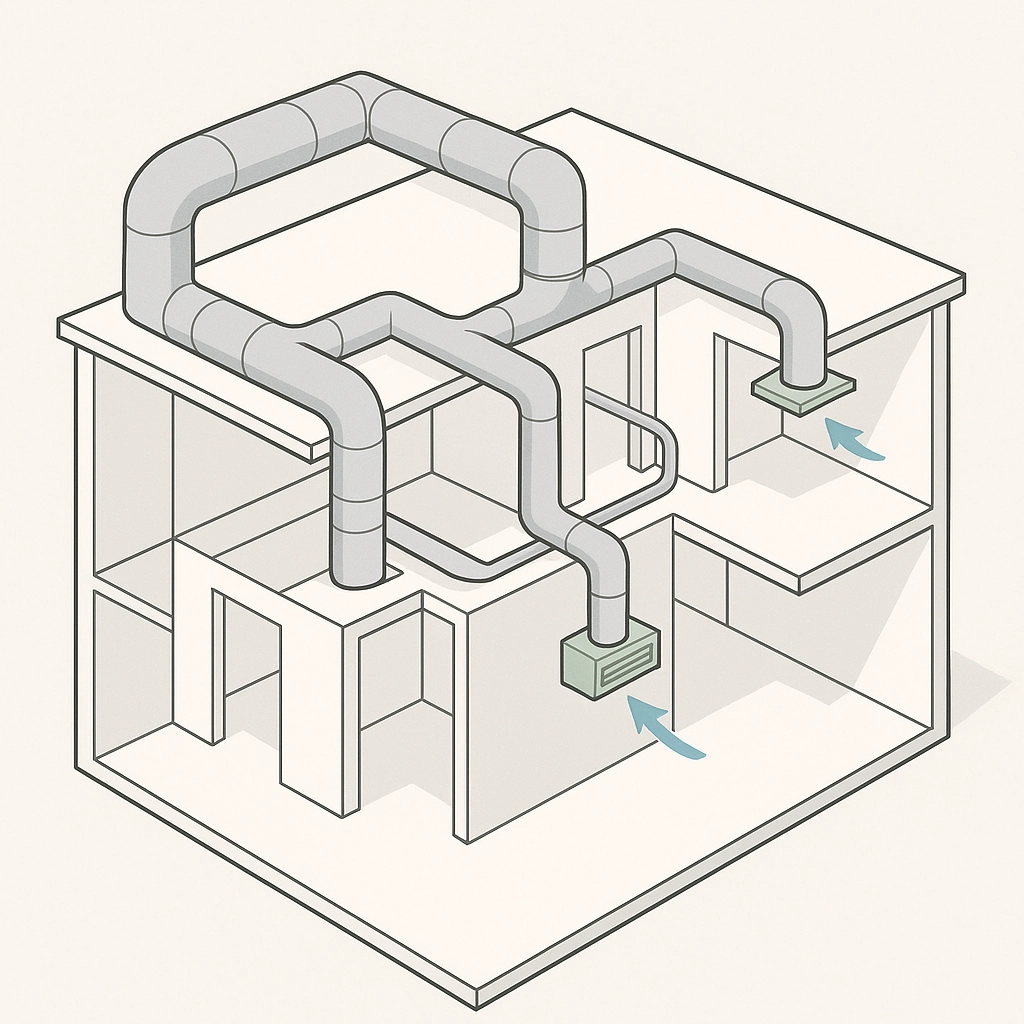

3. Optimize Ductwork and Ventilation Systems

Properly functioning ductwork distributes conditioned air efficiently throughout the building. Poor ductwork wastes significant energy.

Inspect all accessible ductwork for damage. Look for crushed sections, disconnected joints, and holes. Damaged ductwork reduces system efficiency and allows conditioned air to escape into unconditioned spaces.

Seal ductwork joints with appropriate materials. Use metallic tape or duct sealant for permanent repairs. Avoid standard cloth duct tape, which degrades over time. Focus on joints near HVAC equipment where pressure is highest.

Balance airflow throughout the building. Ensure all vents and registers remain open and unobstructed. Closing vents in unused rooms doesn't save energy and can damage equipment by creating improper system pressure.

Clean supply and return vents regularly. Remove dust and debris that restrict airflow. Vacuum vent covers and wipe down surfaces. Consider professional duct cleaning every 3-5 years for buildings with significant dust accumulation.

Verify proper insulation around ductwork in unconditioned spaces. Uninsulated ducts in basements, crawlspaces, and attics lose significant energy. Install appropriate insulation with vapor barriers to prevent condensation.

Check exhaust fan operation in bathrooms and kitchens. Malfunctioning exhaust fans allow moisture buildup, forcing HVAC systems to work harder to maintain comfort. Clean fan blades and verify proper operation.

4. Maintain Water Heating Systems

Water heating typically represents 15-20% of a building's energy consumption. Proper maintenance reduces operating costs and extends equipment life.

Set water heater temperature to 120°F. Higher temperatures waste energy and increase scalding risk. Lower temperatures may allow bacteria growth. Use an accurate thermometer to verify temperature settings.

Insulate hot water pipes and storage tanks. Pipe insulation prevents heat loss during distribution. Tank insulation jackets reduce standby heat loss. Focus on the first six feet of piping from the water heater.

Drain and flush water heater tanks annually. Sediment buildup reduces efficiency and creates hot spots that damage tank interiors. Follow manufacturer procedures for safe draining and refilling.

Replace water heater anode rods as needed. Anode rods prevent tank corrosion but require periodic replacement. Depleted rods allow tank deterioration, reducing efficiency and lifespan.

Check and repair leaking faucets and fixtures. A single dripping hot water faucet can waste hundreds of gallons annually. Replace worn washers, O-rings, and cartridges promptly.

Consider timer controls for electric water heaters. Timers prevent heating during low-demand periods, reducing energy consumption. Program timers based on actual usage patterns.

Install low-flow fixtures where appropriate. Low-flow showerheads and faucets reduce hot water demand without sacrificing performance. Choose models with good user ratings for best results.

5. Implement Smart Controls and Professional Maintenance

Smart building controls optimize energy consumption based on occupancy and usage patterns. Regular professional maintenance ensures all systems operate efficiently.

Install programmable or smart thermostats. These devices automatically adjust temperatures based on schedules, reducing energy consumption during unoccupied periods. Smart thermostats learn usage patterns and make automatic adjustments.

Program thermostats for optimal efficiency. Set back temperatures by 7-10°F during unoccupied hours. Each degree of setback saves approximately 10% on heating and cooling costs.

Schedule preventive maintenance contracts with qualified technicians. Professional maintenance identifies problems before they cause energy waste or equipment failure. Annual contracts often cost less than emergency repairs.

Monitor energy consumption regularly. Install energy monitoring systems to track usage patterns and identify inefficiencies. Monthly reviews help identify problems quickly.

Maintain building automation systems properly. Clean sensors, calibrate controls, and update software regularly. Malfunctioning automation systems can waste significant energy through improper operation.

Train building occupants on energy-efficient practices. Simple actions like closing doors, reporting problems promptly, and following temperature guidelines contribute to overall efficiency.

Document maintenance activities and results. Keep records of filter changes, repairs, and energy consumption. This data helps optimize maintenance schedules and identify recurring problems.

Results and Implementation

These maintenance strategies provide measurable energy savings within the first month of implementation. Proper air sealing alone can reduce energy costs by 15-20%. Combined with regular equipment maintenance, total savings often exceed 30%.

Start with the highest-impact items: filter replacement, air sealing, and thermostat programming. These require minimal investment but provide immediate returns. Progress to more complex tasks like ductwork sealing and professional maintenance scheduling.

Monitor results through utility bill tracking and energy audits. Document improvements to justify continued investment in preventive maintenance programs. Use savings to fund additional efficiency improvements and equipment upgrades.

For comprehensive building maintenance services, including energy efficiency optimization, contact our professional team for customized solutions that maximize your property's performance and profitability.

Comments